A steam trap is an automatic valve designed to manage condensate (liquid formed when steam releases heat energy) and non-condensable gases (such as air) within a steam system.

Steam traps are crucial components in any steam system, ensuring that your operations run smoothly and efficiently. They work by removing condensate, air, and other non-condensable gases while preventing the loss of live steam. This not only improves the efficiency of your system but also helps reduce energy costs and prevent damage to your equipment.

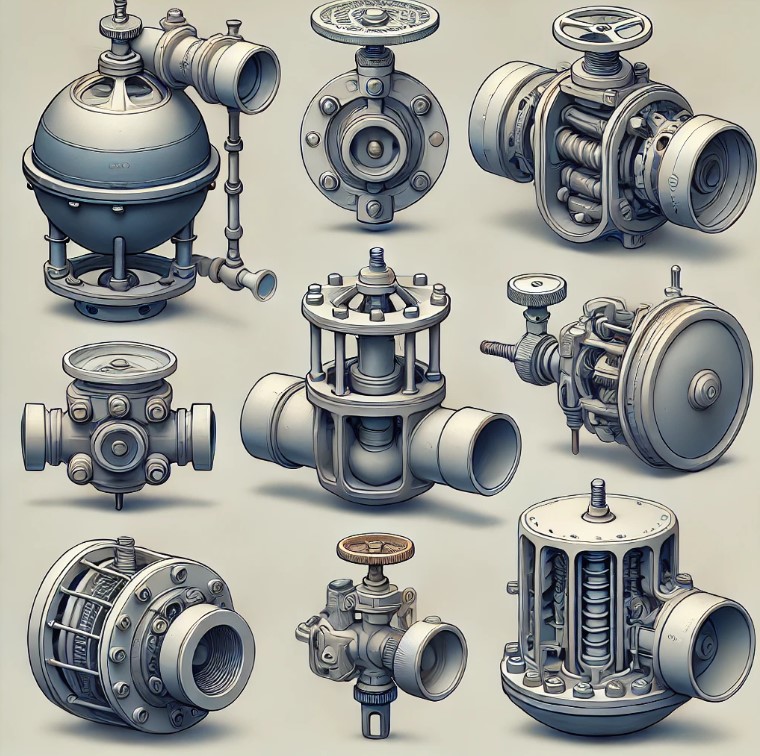

Understanding the different types of steam traps can help you choose the right one for your system:

Float and Thermostatic Traps: Ideal for systems with varying loads, these traps use a float to discharge condensate and a thermostatic element to vent air.

Inverted Bucket Traps: Known for their durability, these traps use an inverted bucket mechanism to discharge condensate when it fills up.

Thermostatic Traps: These traps respond to temperature changes, opening when condensate cools and closing when steam is present.

Disc Traps: Compact and versatile, disc traps use pressure differences to manage condensate and steam.

Selecting the right steam trap for your application is essential. Choosing the right steam trap and body material can make all the difference. Do keep in touch with us to make that choice easy.