Description

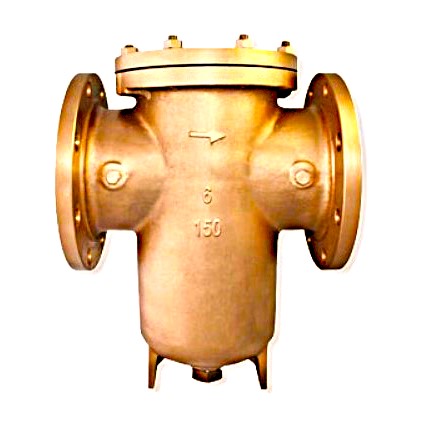

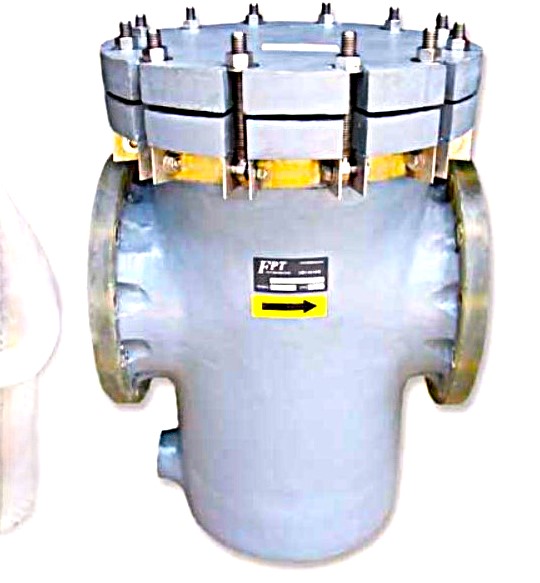

The basket strainers protect equipment by mechanically removing solids from liquids and other commercial and industrial piping systems with the use of a perforated or wire mesh straining screen in a vertically oriented chamber. Basket strainers have more debris holding capacity than Y strainers, and generally have less of a pressure drop, which is why they are ideal in liquid applications.

These strainers are usually supplied in one of four materials: iron, carbon steel, bronze, or stainless steel. Iron is used most often because it costs the least, and has good corrosion resistance in water and many other services. Carbon steel is used where higher temperatures, or concern with thermal or mechanical shock is an issue, which makes them popular in the oil and petrochemical industries. Bronze handles thermal and mechanical shock better than iron, and is better in some corrosive applications, but is limited in temperature range. Stainless steel is needed where corrosion could be an issue, and is widely used in the chemical, food, and pharmaceutical industries.

They are provided with a variety of end connections, including threaded, flanged, and welded. Standard screens are provided for either WOG (water, oil, gas) or steam service, but other screens are available on request.

Reviews

There are no reviews yet.