Description

| Range Of Applications: | Power Station, Life, Industrial | Type: | Natural Circulation/Once Through |

|---|---|---|---|

| Certificate: | ISO,ASME | Output: | Hot Water/Steam |

| Fuel: | Coal/Gas/Oil-fired, Water Heat | Name: | Furnace Economizer |

| High Light: |

power plant economizereconomizer for boiler |

||

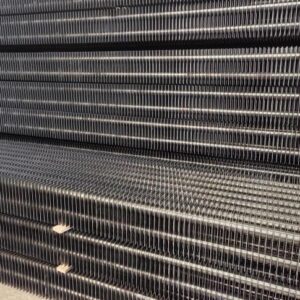

Economizer

- Description :Economizer is a mechanical device intended to reduce energy consumption, or to perform another useful function like preheating a fluid. The economizer is used for other purposes as well boiler, powerplant, and heating, ventilating, and air-condition in(HVAC) uses are discussed in this article. In simple terms, an economizer is a heat exchanger.Features :

- Recovering heat from the waste gas.

- Increase thermal efficiency and reduce fuel consumption

- Heat Pipes have high heat transfer efficiency due to two modes of heat transfer in the tube – conduction and convection

- Simplicity in installation

- Compact design allows more space for other equipment in crowded mechanical rooms

- Require no external power for operation

Specifications

| Description | Boiler economizer |

| Material | Alloy steel, Carbon steel, SA210C ,SA213T22, etc. |

| Material standard | ASTM, EN or ISO etc. |

| Dimension | Customization |

| Weight | Min: 10 ton

Max.:1000 ton |

| Smelting Process: | EF+LF + VD |

| Process | Material→Ingot → Hot/Cold-Rolling→ Heat treatment (Normalizing+ tempering) → Inspection →rough machining UT →2nd Heat treatment →finishing machining →Inspection |

| UT standard | ASTM A388 or EN10228, etc |

Reviews

There are no reviews yet.